Our FrameStar® two-component technology reduces evaporation from PCR plates, improving your results and allowing you to reduce the volume of expensive reagents to save you money.

FrameStar® plates combine the advantages of thin-walled polypropylene tubes for optimum PCR results, with a rigid polycarbonate frame to increase the thermal stability of the plate during the PCR process. This means that compared to a standard polypropylene plate, the FrameStar® plate will not warp and expand during rapid heating and cooling, meaning the integrity of seals will remain consistent and therefore less of your sample will evaporate.

This in turn means you can spend less money on expensive reagents, as you are retaining more during the PCR process.

For Instrument Compatibility Table Click here

Why our FrameStar® 2-component design is superior to standard polypropylene plates

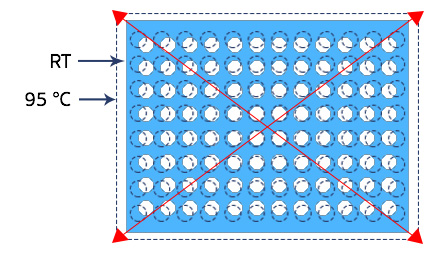

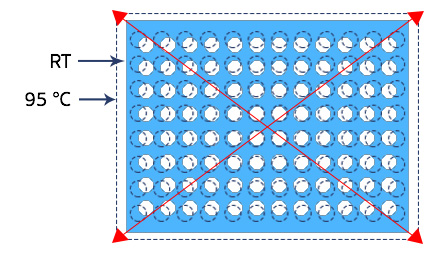

FrameStar® PCR plates maximise thermal stability at high temperatures, which prevents sample loss by minimising thermal expansion during PCR. The two-component design combines the advantages of thin wall polypropylene tubes for optimum PCR results, and a rigid polycarbonate skirt and deck for the highest thermal stability and rigidity. In contrast to standard one-piece PCR plates, evaporation from the corner positions of the plate and outer rows of wells is minimal, which allows for the downscaling of reagent volumes and therefore saves costs.

- Two-component technology reduces thermal expansion and sample evaporation.

- Reduction of evaporation leads to improved consistency of PCR results.

- Well spacing and position post-PCR remain accurate so liquid handling devices can reliably add or remove the smallest quantities from the plate.

- Ideal for robotics, as plate distortion is eliminated post-PCR.

- FrameStar® is ideal for assay miniaturisation due to rigid skirt eliminating warping, giving better sealing properties.

- Cost saving due to downscaling of reaction volumes.

- Lack of warpage reduces variation of fluorescent signals in optical assays, such as qPCR.

Thermal expansion of Polypropylene (PP) plates leads to evaporation from outer wells

PP is the optimum material for PCR tubes. It provides the most efficient heat transfer, as well as an inert surface with low binding capabilities for nucleic acids, proteins and other molecules. However, the material is not thermally stable in a plate format, and expands and contracts during each PCR cycle. Such thermal expansion will weaken the plate seal and leads to sample evaporation mainly from corner wells and outer rows.

The FrameStar® Range

Polypropylene wells, polycarbonate frame, cut corner A24, working volume: <30 µl, total well capacity: 55 µl; designed for use on standard thermal cyclers

Polypropylene wells, polycarbonate frame, cut corners A24 and P24, working volume: <30 µl, total well capacity: 55 µl; designed for use on the Roche LightCycler® 480 with 384 well block

Polypropylene wells, polycarbonate frame, cut corner A1, no grid reference, working volume: <30 µl, total well capacity: 55 µl; designed as a half size 384 well plate for lower sample throughput

Low profile, 0.1 ml polypropylene wells, rigid polycarbonate frame, cut corner H1, working volume: <100 µl, total well capacity: 200 µl; now also available as low binding plate with ultra-low DNA binding properties

Standard profile, 0.2 ml polypropylene wells, polycarbonate frame, cut corner H1, working volume: <200 µl, total well capacity: 300 µl; universal semi-skirted plate designed for use on standard thermal cyclers

Low profile, 0.1 ml polypropylene wells, polycarbonate frame, cut corner H12, working volume: <100 µl, total well capacity: 200 µl; designed for use on Roche LightCycler® 480 with 96 well block

Low profile, 0.1 ml polypropylene wells, polycarbonate frame, cut corner H12, working volume: <100 µl, total well capacity: 200 µl; designed for use on Roche LightCycler® 480 with 96 well block; extra white wells for improved sensitivity in fluorescent assays

Standard profile, 0.2 ml polypropylene wells, polycarbonate frame, cut corner A12, working volume: <200 µl, total well capacity: 300 µl; designed for use on all major cyclers, including ABI® instruments with standard 96 well blocks; now also available as low binding plate with ultra-low DNA binding properties

Low profile, 0.1 ml polypropylene wells, polycarbonate frame with upstand, cut corner A1, working volume: <100 µl, total well capacity: 200 µl; designed for use on ABI® Fast Block cyclers

Standard profile, 0.2 ml polypropylene wells, polycarbonate frame with upstand, cut corner A12, working volume: <200 µl, total well capacity: 300 µl; designed for use on ABI® instruments

Standard profile, 0.2 ml polypropylene wells, polycarbonate frame, cut corner H1, working volume: <200 µl, total well capacity: 300 µl; universal non-skirted plate designed for use on all major thermal cyclers

Low profile, 0.1 ml polypropylene wells, polycarbonate frame, cut corner H1, working volume: <100 µl, total well capacity: 200 µl; universal non-skirted, low profile plate designed for use on all major thermal cyclers

96 well semi-skirted plate, vertically scored, snaps easily into strips of 8 tubes or part plates, cut corner A12; standard profile, 0.2 ml polypropylene wells, polycarbonate frame, working volume: <200 µl, total well capacity: 300 µl

96 well semi-skirted plate, vertically scored, snaps easily into strips of 8 tubes or part plates, cut corner A12; low profile, 0.1 ml polypropylene wells, polycarbonate frame, working volume: <100 µl, total well capacity: 200 µl